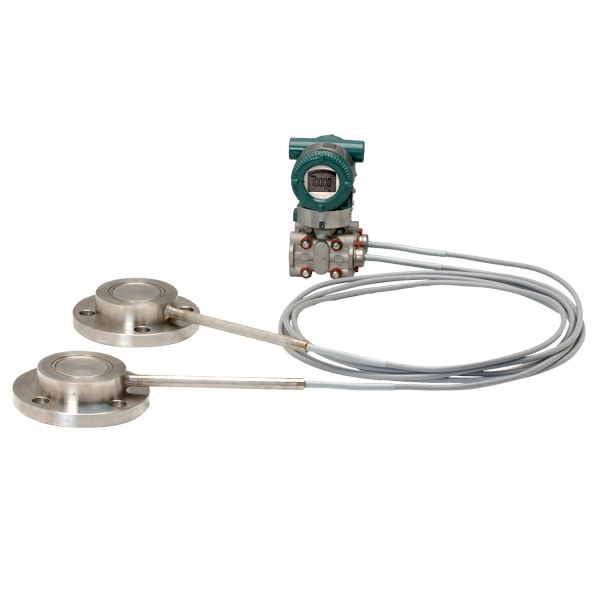

Part Number: EJA210E-JMS4C-912EN-WA13C2SW00-B/D4Model: EJA210E Flange Mounted Differential Pressure Transmitter

Manufacturer: Yokogawa

Ordering Information

- Model: EJA210E - Flange mounted differential pressure transmitter

- Output Signal: -D - 4 to 20 mA DC with digital communication (BRAIN protocol)

- Measurement span (capsule): M - 1 to 100kPa (4 to 400 inH2O)

- Low pressure side wetted parts material: S -

Cover flange and process connector: ASTM CF-8M?

Capsule: Hastelloy C-276? (Diaphragm) F316L SST, 316L SST (Others)

Capsule gasket: Teflon-coated 316L SST

Drain/Vent plug: 316 SST - Low pressure side Process connections: 4 - with 1/2 NPT female process connector

- Coverflange bolts and nuts material: G - 316L SST

- Installation: -9 - Horizontal piping type and left side high pressure

- Amplifier housing: 1 - Cast aluminium alloy

- Electrical connection: 2 - 1/2 NPT female, two electrical connections without blind plugs

- Integral Indicator: D - Digital indicator?

- N - always N

- Process connection style: W - Flush type

- Flange rating: J1 - JIS 10K

- Flange size: 3 - 3-inch (80mm)

- Flange material: B - 304 SST4

- Gasket contact surface5: 2 - Flat (no serration)

- Wetted parts material (high pressure side)6: SW - [Diaphragm] 316L SST; [Others] 316 SST

- Flushing connection ring7: 0 - None

- Extension: 0 - None

- Fill fluid: -A - For high temperature use (Silicone oil)

Process temperature: -10 to 250?C

Ambient temperature: -10 to 85?C - Calibration unit8: /D4 - M calibration (kgf/cm? unit)

NOTE:

- Cast version of 316 SST. Equivalent to SCS14A.

- Hastelloy C-276 or ASTM N10276.

- Not applicable for output signal code G.

- Forged version of the material may be used.

- See Table 3 ?asket contact surface?n Page 5.

- Users must consider the characteristics of selected wetted parts material and the influence of process fluids. The use of inappropriate materials can result in the leakage of corrosive process fluids and cause injury to personnel and/or damage to plant facilities. It is also possible that the diaphragm itself can be damaged and that material from the broken diaphragm and the fill fluid can contaminate the user? process fluids.

Be very careful with highly corrosive process fluids such as hydrochloric acid, sulfuric acid, hydrogen sulfide, sodium hypochlorite, and high-temperature steam (150?C [302?F] or above). Contact Yokogawa for detailed information of the wetted parts material. - When specified flushing connection ring code A or B, exclusive gasket is provided for transmitter side.

- In case of wetted parts material code TW (Tantalum), the process temperature limit is ? to 200?C.

- Estimated Lead Time: 8 - 10

- Shipping Weight: 18 Kg