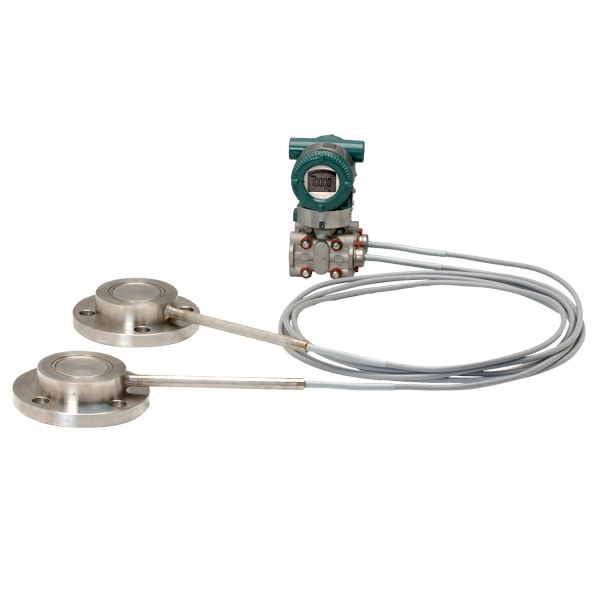

Part Number: EJA120E-JES4G-91CEJ/KU22/M11Model: EJA120E Differential Pressure Transmitter

Manufacturer: Yokogawa

Condition: New & Original in Factory Packing

Factory Warranty: 12 Months

Ordering Information

| Model | EJA120E | Differential pressure transmitter |

| Output signal | -J | 4 to 20 mA DC with digital communication (HART 5/HART 7 protocol)(1) |

| Measurement span (capsule) | E | 0.1 to 1 kPa (0.4 to 4 inH2O) |

| Wetted parts material(2) | S# | Cover flange and process connector: ASTM CF-8M(3)

Capsule:

Hastelloy C-276(4) (Diaphragm)

F316L SST, 316L SST (Others)

Capsule gasket: PTFE Teflon

Vent/Drain plug: 316 SST |

| Process connections | 4 | with 1/2 NPT female process connector |

| Bolts and nuts material | G | 316L SST |

| Installation | ?-9 | Horizontal piping and left side high pressure |

| Amplifier housing | 1 | Cast aluminum alloy |

| Electrical connection | C | 1/2 NPT female, two electrical connections and a SUS316 blind plug |

| Integral indicator | E | Digital indicator with the range setting switch (push button)(5) |

| Mounting bracket | J | 316 SST 2-inch pipe mounting, flat type (for horizontal piping) |

| ATEX | /KU22 | Combined KF22, KS21 and ATEX Intrinsically safe Ex ic(6)(7)

[ATEX Intrinsically safe Ex ic]

Applicable Standard: EN 60079-0, EN 60079-11

II 3G Ex ic IIC T4 Gc, Amb. Temp.: ?C30 to 60??C (?C22 to 140??F)(8)

Ui=30 V, Ci=27.6 nF, Li=0 ??H |

| Material certificate(9) | /M11 | Cover flange, Process connector(10) |

The ????? marks indicate the most typical selection for each specification.

- HART 5 or HART 7 is selectable. Specify upon ordering.

- Users must consider the characteristics of selected wetted parts material and the influence of process fluids. The use of inappropriate materials can result in the leakage of corrosive process fluids and cause injury to personnel and/or damage to plant facilities. It is also possible that the diaphragm itself can be damaged and that material from the broken diaphragm and the fill fluid can contaminate the user??s process fluids.

Be very careful with highly corrosive process fluids such as hydrochloric acid, sulfuric acid, hydrogen sulfide, sodium hypochlorite, and high-temperature steam (150??C [302??F] or above). Contact Yokogawa for detailed information of the wetted parts material. - Cast version of 316 SST. Equivalent to SCS14A.

- Hastelloy C-276 or ASTM N10276.

- Not applicable for output signal code F.

- Applicable for Electrical connection code 2, 4, 7, 9, C and D.

- Not applicable for output signal code Q.

- Lower limit of ambient temperature is ?C15??C (5??F) when /HE is specified.

- Material traceability certification, per EN 10204 3.1B.

- Applicable for process connections codes 1, 2, 3, and 4.

- Estimated Lead Time: 10 - 12

- Shipping Weight: 8 Kg