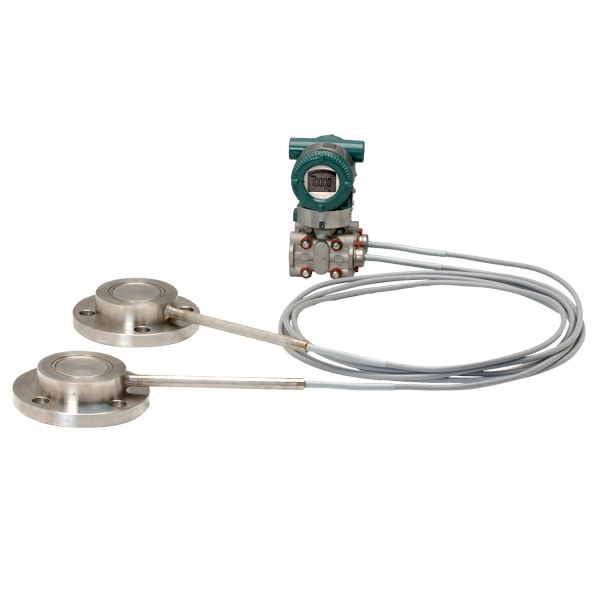

Part Number: EJA440E-DCS4J-719DD/KF22/D3Model: EJA440E Gauge Pressure Transmitter

Manufacturer: Yokogawa

Condition: New & Original in Factory Packing

Factory Warranty: 12 Months

Ordering Information

| Model | EJA440E | Gauge pressure transmitter |

| Output signal | -D | 4 to 20 mA DC with digital communication (BRAIN protocol) |

| Measurement span (capsule) | C | 5 to 32 MPa (720 to 4500 psi) |

| Wetted parts material(1) | S# | Cover flange: F316 SST(2)

Process connector: ASTM CF-8M(2)(3) (C-capsule), 316 SST(2) (D-capsule)

Capsule: Hastelloy C-276(4) (Diaphragm), F316L SST, 316L SST (Others)

Capsule gasket: Teflon-coated 316L SST

Vent/Drain plug: 316 SST |

| Process connections | 4 | with 1/2 NPT female process connector(5)(6) |

| Bolts and nuts material | J | B7 carbon steel |

| Installation | -7 | Vertical piping, left side high pressure, and process connection down side |

| Amplifier housing | ?1 | Cast aluminum alloy |

| Electrical connection | 9 | M20 female, two electrical connections and a blind plug(7) |

| Integral indicator | D | Digital indicator(8) |

| Mounting bracket | D | 304 SST or SCS13A 2-inch pipe mounting, L type (for vertical piping) |

| ATEX | /KF22 | ATEX Flameproof Approval(9)

Applicable Standard: EN IEC 60079-0, EN 60079-1, EN 60079-31

Certificate: KEMA 07ATEX0109 X

II 2 G Ex db IIC T6...T4 Gb, II 2 D Ex tb IIIC T85??C Db

Degree of protection: IP66/IP67

Amb. Temp. (Tamb) for gas-proof :

T4; ?C50 to 75??C (?C58 to 167??F), T5; ?C50 to 80??C (?C58 to 176??F), T6; ?C50 to 75??C (?C58 to 167??F)

Process Temp. for gas-proof (Tp):

T4; ?C50 to 120??C (?C58 to 248??F), T5; ?C50 to 100??C (?C58 to 212??F), T6; ?C50 to 85??C (?C58 to 185??F)

Max. surface Temp. for dust-proof: T85??C (Tamb: ?C30 to 75??C, Tp: ?C30 to 85??C)(10) |

| Calibration units(11) | /D3 | bar calibration (bar unit) |

The ??#??marks indicate the construction materials conform to NACE material recommendations per MR0175/ISO 15156. Please refer to the latest standards for details. Selected materials also conform to NACE MR0103.

The ????? marks indicate the most typical selection for each specification.

- Users must consider the characteristics of selected wetted parts material and influence of process fluids. Specifying inappropriate materials has the potential to cause serious damage to human body and plant facilities resulted from an unexpected leak of the corrosive process fluids.

- Intergranular corrosion test passed according to ASTM A262 Practice E.

- Cast version of 316 SST. Equivalent to SCS14A.

- Hastelloy C-276 or ASTM N10276.

- Specify the process connections code 3 or 4, when using the process connector for D capsule. Without the process connector, use the 1/4 NPT male piping to directly connect to the cover flange.

- Lower limit of ambient and process temperature is -15??C for capsule code C.

- Material of a blind plug; aluminum alloy for code 5 and 9, and SUS304 for code 7.

- Not applicable for output signal code G.

- Applicable for Electrical connection code 2, 4, 7, 9, C and D.

- Lower limit of ambient temperature is ?C15??C (5??F) when /HE is specified.

- The unit of MWP (Max. working pressure) on the name plate of a housing is the same unit as specified by option codes D1, D3, and D4.

NOTE: This is a replacement of EJA440A-DCS4A-79DC/KF2/D3

- Estimated Lead Time: 12 - 16

- Shipping Weight: 10 Kg